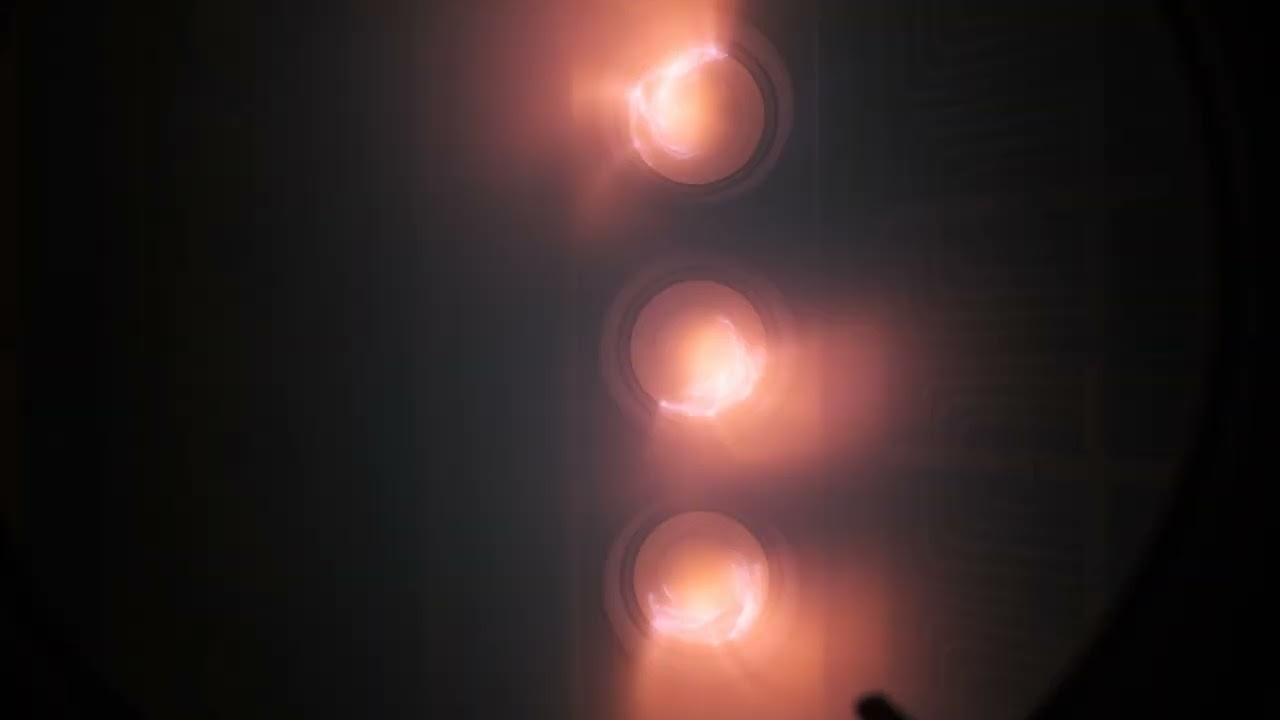

INVENTAシステムプラットフォームは、アドバンスト・アークテクノロジー(AAT)による最先端のソリューションを提供します。この革新的な技術は、トリガー(アーク着火機構)、ハイエンドのアークソース設計、および迅速に調整可能な電磁界、これらを完璧にチューニングした相互作用により、比類のない汎用性を提供します。

これらの重要なコンポーネントは、INVENTAを効率的で信頼性できる生産性の高いシステムにし、均一なコーティングを可能にするために大幅に強化されています。AATは、これまで以上に高品質のコーティングを提供します。