We help our customers to become more sustainable and efficient. Emissions reduction in transportation, maximized longevity and performance of tools, increased energy efficiency, intelligent materials and sustainable polymer processing are proven hallmarks of our global leadership. Everything we invent, develop and do is guided by our passion to support our customers’ goals and foster a sustainable world.

Empowering Customers to Achieve More With Less

-

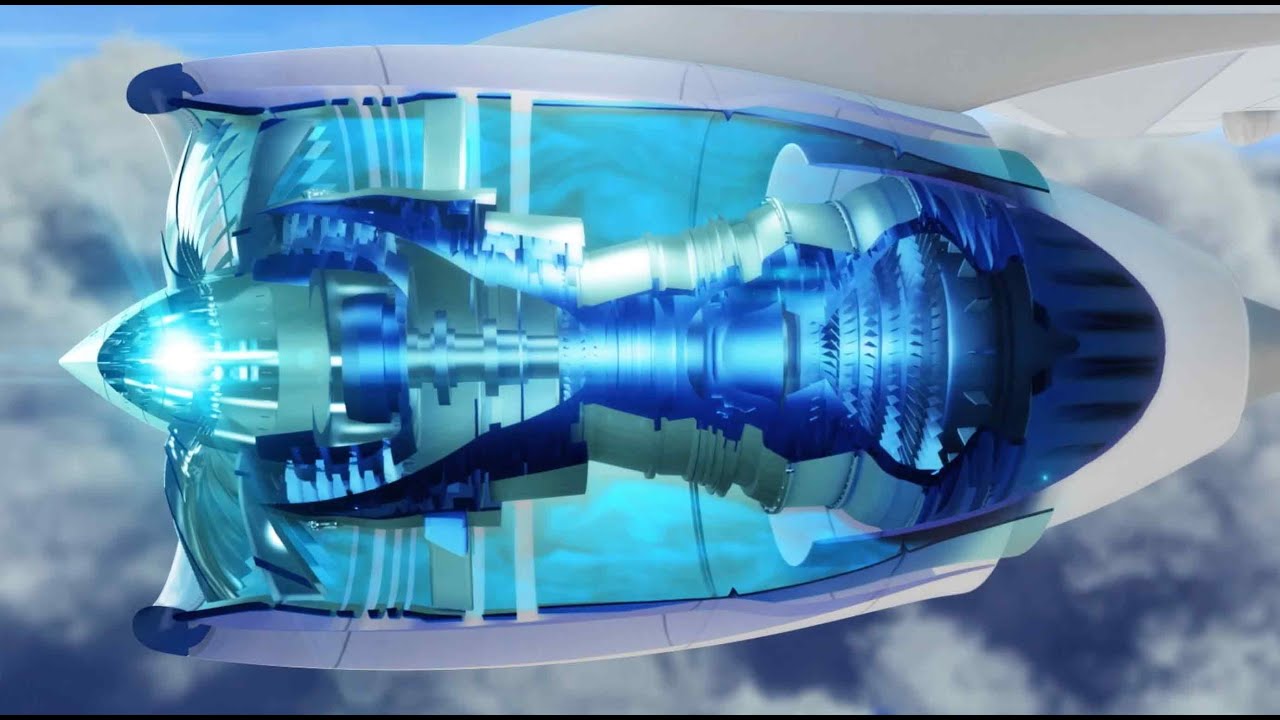

+5% efficiency

5% efficiency increase in jet engines through coatings is equivalent to ~26 million metric tons of CO2 reduction annually2 or 88% of Swiss CO2 emissions.1

-

-10% weight

Coatings enable the use of lightweight car materials, which will extend the driving range. For a 650-km range EV that is 10% lighter, the range extends by 5–7%, equivalent to a marathon.

-

-28% emissions

Coating extends a tool’s lifetime by 20x. For the total number of tools coated by Oerlikon annually, ~8.3 million metric tons of CO2 is avoided or 28% of Swiss CO2 emissions.1

-

-26% energy

Insulating covers for hot runners reduce heat dissipation and can save ~26% of energy consumption.

Our business objective is to provide customers with solutions that make their production processes more efficient and their products more durable. Our solutions and services, together with our advanced materials, improve and maximize the performance, function, design and sustainability of our customers’ and their customers’ products and manufacturing processes in key industries, as well as those of their customers. By increasing efficiency, we enable customers to optimize their usage of resources, lessen their energy consumption and reduce waste and emissions.

1A total of 29.6 million metric tons in 2022, based on the report “CO2 statistics: Emissions from thermal and motor fuels” by the Swiss Federal Office for the Environment. 2Based on the installed base of jet engines in 2019.

More About Innovation at OerlikonLeveraging Our Innovative and Sustainable Technology

-

Purpose

Our purpose is to maintain technology leadership and enable industries and customers to do more with less.

-

Vision

Our vision is to empower customers to increase their efficiency and productivity, optimize their use of resources and reduce their energy use, water consumption and waste.

-

Focus

We focus on helping customers and end users reduce environmental footprint while reducing Oerlikon's own impact, as well as ensuring strong health, safety and employment culture while upholding good governance and stakeholder engagement.

Advanced PFAS-free coatings for a safer and better tomorrow

Discover advanced PFAS-free coatings that combine high performance with environmental compliance. Engineered for durability, low friction, and harsh conditions - without the risks of “forever chemicals.”