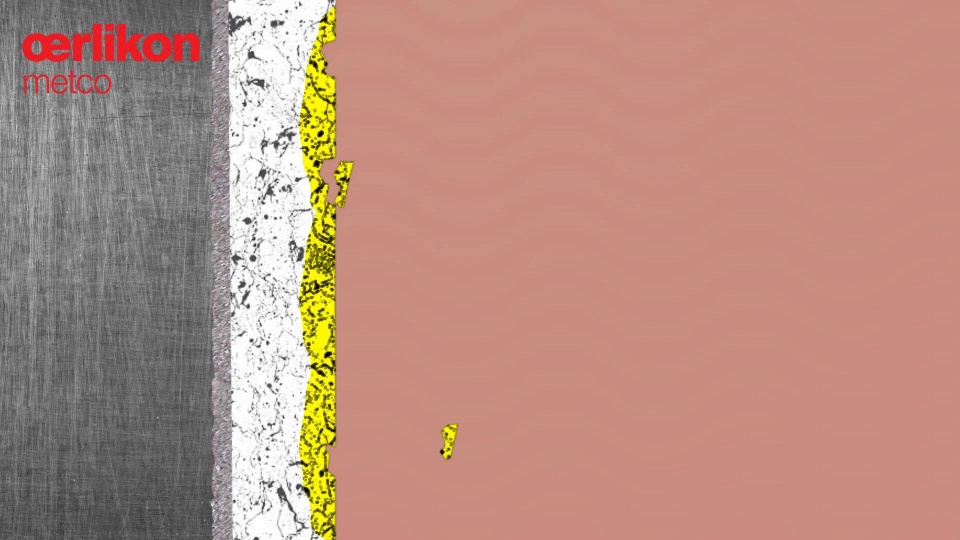

CMAS (calcia-magnesia-alumina-silicate) is debris that exists in the atmosphere as a result of volcanic activity and other natural and industrial processes. In systems that cycle from very high temperatures to ambient temperatures, CMAS is known to attack EBCs (environmental barrier coatings) and TBCs (thermal barrier coatings), both of which are used in the hot sections of modern gas turbine engines. The CMAS particulate is ingested into the engine, where it becomes molten in the hot section areas where they solidify on cooling to form deposits on turbine components. However, the CMAS and the ceramics used for EBCs and TBCs have very dissimilar thermal expansion coefficients causing the EBC or TBC to crack, spall, and fail.

CMAS Attack

Solutions:

Oerlikon Metco works closely with turbine engine OEMs to develop new coating solutions and systems that are resistant to CMAS attack. These solutions can involve new ceramic compositions and application methods, often in multi-layer and gradient coatings. These solutions are especially important to protect ceramic matrix composites that are essential to the new generation of turbine engines.