Sliding wear is a general term for the mechanism of removing material due to sliding contact of solid surfaces. Due to the relative motion at the contact area, material may be removed from one part or both. Sliding wear may appear with adhesive wear and abrasive wear depending on the relative surface speed, surface hardness and coefficient of friction. A common method to rank surfaces on sliding wear is the Block-on-Ring-Test (ASTM G77).

Sliding Wear

Solutions:

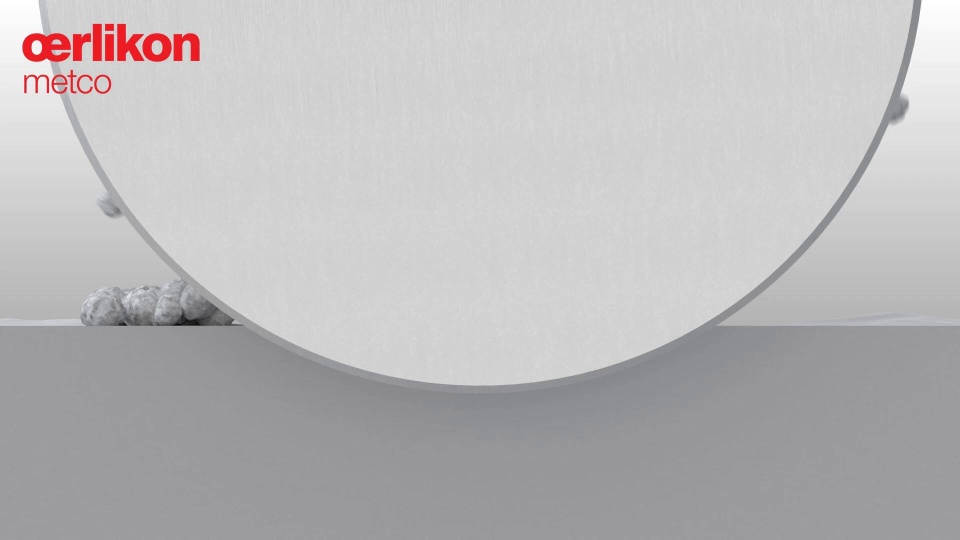

In paper manufacturing, large rolls with a specific surface finish are used to ‘polish’ the paper. This process is called calendering. As the paper is moving over the roll at very high speeds, sliding wear is a concern. Oerlikon Metco coating solutions that are specially designed for calender rolls ensure that the surface provides the correct finish on the paper while protecting the roll from sliding wear.

When polyester or polyester-cotton thread is first produced, it is hard and relatively inflexible. Thread manufactures pass the thread at very high speeds and under tension across a series of heated (stretch) and chilled-(tow) rollers to soften the tread so it can be used for apparel and other uses. The stretch and tow rolls are coated with thermal sprayed ceramic coatings that are subsequently highly finished. The coatings protect the rolls from sliding wear and prevent breakage of the thread.